|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

The power cylinders consist essentially of an air cylinder and a built-in hydraulic intensifier. As a result, the full stroke can be subdivided into two distinct phases:

When the moving ram meets a resistance at any point during its travel, the working stroke can be engaged. Their reliability, thanks to their simple design and constant quality control, is proven by more than 30,000 units that work throughout the world. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

AX Series Power Cylinders have the same technical and functional characteristics as the AP Series. Thanks to their compact shape, the AX Series can be used when lower overall height is required. The AX Series configuration allows longer standard approach and working strokes, than the AP Series. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

The UP Series Power Cylinders consist of a hydraulic intensifier which permits immediate use of the force. They are designed for applications where approach stroke is not required. Essential features:

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

Grant Hydro-Pneumatic Presses are an excellent combination of flexibility and simplicity. These cylinders are a combination of two principals, namely; the speed of compressed air and the power of hydraulics. Our practical experience in this design gives us a product that offers high cycling and long life. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

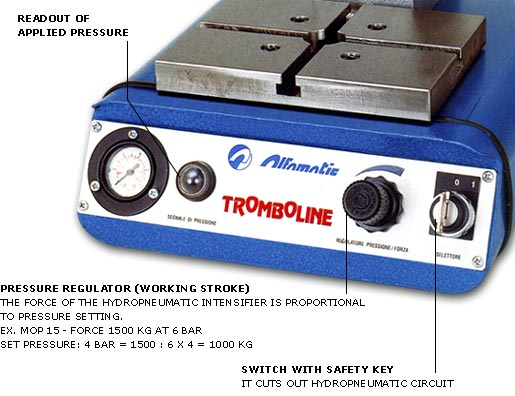

The power set of the Tromboline consists of a hydro-pneumatic intensifier and a manually operated mechanical unit. The MOP Series Press uses air to oil intensification combined with a manual approach to make a unit that is rapid and lessens operator strain. We offer the MOP 07, MOP 15, MOP 30 and MOP 50. Each model has 4 hydro-pneumatic working strokes of 5, 10, 15, 20 mm and a total stroke length of 60mm. Force up to 11,024 lbs @ 87 PSIG

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Grant's "Perfect Riveting"™ System is available for this product

![]()

- | Home | Products | Services | What's New | Processes | Literature | Contact Us |

-

|

Riveting Methods

|

Search

|

Feedback

|

90 Silliman Avenue, PO Box 3350, Bridgeport, Connecticut, USA, 06605

Phone: 203-366-4558, 800-227-2150, Fax: 203-366-0370 - Email: sales@grantriveters.com - Copyright © Grant Riveters 2004.

Last modified on Tuesday July 13, 2010